Since 2010, Sedal Technical Ceramics has specialized in the design and manufacturing of high-performance technical ceramic components for demanding industries such as electronics, energy, automotive, chemical, food, and sanitary applications.

We operate globally, supplying millions of ceramic parts every year from our own fully integrated production facilities, always in compliance with the highest international quality standards.

We build long-term partnerships based on trust, reliability, and a deep understanding of our customers’ needs, no matter where they are or what language they speak.

With 15 years of manufacturing experience and continuous R&D, we have developed proprietary materials such as SEDALOX®, our exclusive alumina with Nano Shelter Technology, designed to deliver consistent and exceptional performance.

Sedal Technical Ceramics, your trusted partner in technical ceramics

Our proprietary manufacturing process allows us to create exclusive OEM products using custom-designed raw material formulas with tailored compositions. We offer high-precision mold manufacturing, advanced production methods, rapid CNC prototyping, and fully equipped facilities with cutting-edge inspection instruments.

We start with high-purity ceramic powders (e.g., alumina, zirconia) which are carefully selected, blended with binders and additives, and milled into a homogeneous slurry. This ensures consistency in composition and optimal performance during shaping and sintering.

The slurry is spray-dried into fine, free-flowing granules. These granules are ideal for compacting, ensuring uniform density and optimal shaping in the next step.

Using high-precision moulds and pressing techniques (uniaxial or isostatic), we compact the granules into solid “green bodies” with defined geometry and excellent structural integrity.

The green parts are fired at high temperatures to achieve full densification. This critical step fuses the particles, eliminates undefined porisity, and gives the ceramics their final mechanical strength and performance characteristics.

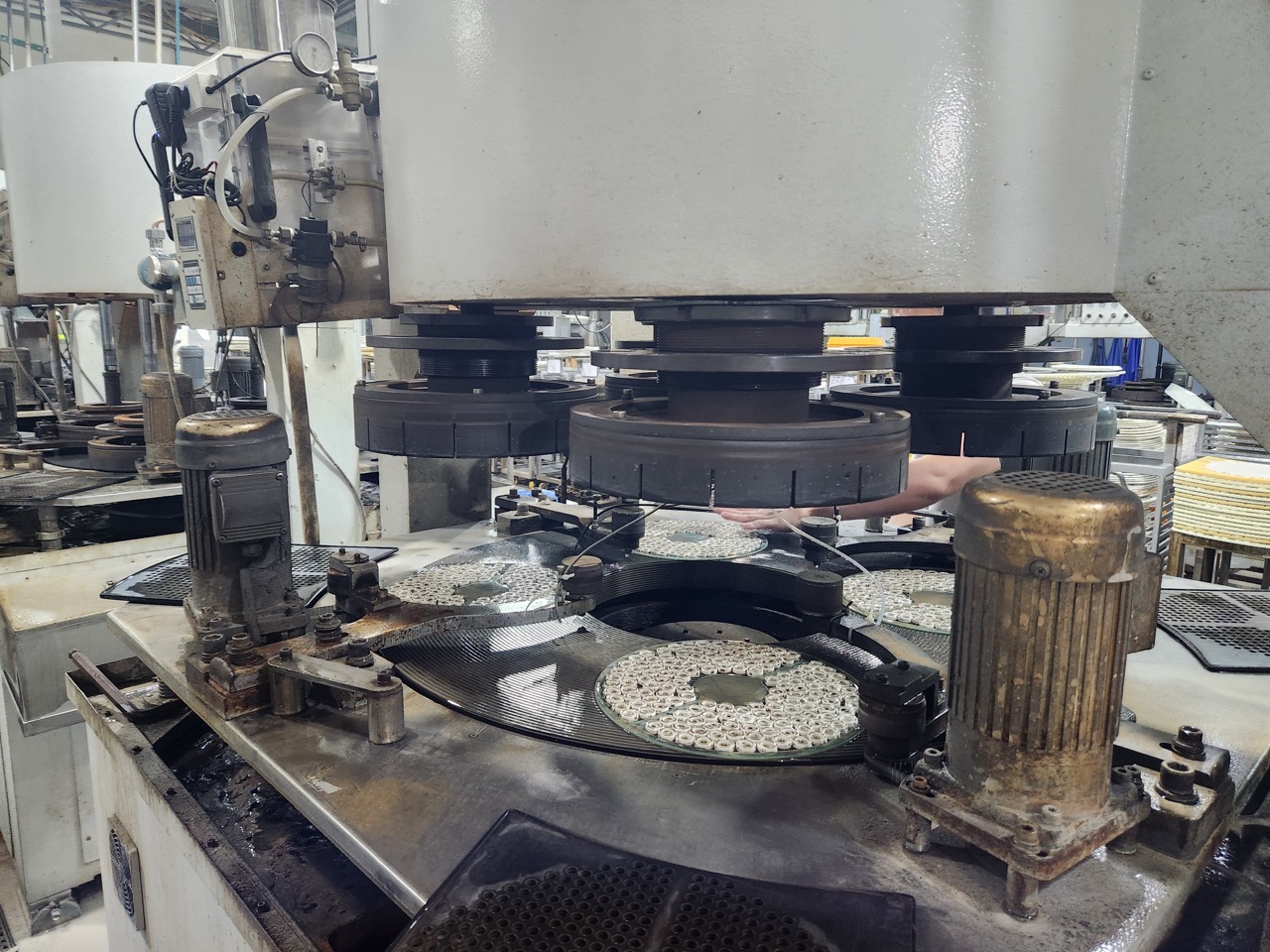

After sintering, components are machined, lapped or polished (if required) to achieve tight tolerances and the desired surface finish — especially important in demanding OEM applications.

Every part undergoes 100% inspection, including dimensional checks, surface analysis and performance validation, ensuring compliance with the most rigorous quality standards.

We manufacture our products using a range of advanced ceramic materials, each tailored to meet the specific demands of its final application. Thanks to our strong R&D capabilities, we develop customized formulations — including SedalOX™, our proprietary 96% alumina (Al₂O₃) Ready-To-Press (RTP) powder enhanced with Nano Shelter Technology™. This innovation delivers superior performance, durability, and reliability across a wide range of technical and industrial applications.

| Properties | Units | Standard | DP-AL996 | SEDALOX | SEDALOX-WS | TC-996 | TC-96 |

|---|---|---|---|---|---|---|---|

| Main Material | % | Type of material | ALUMINA (99,6%) | ALU MINA (96%) | ALU MINA (96%) | ALUMINA (99,6%) | ALUMINA (96%) |

| Density | g/cm3 | EN - 623 | ≥3.9 | ≥3.7 | >3.7 | ≥3.85 | ≥3.7 |

| Flexura! Strength | Mpa | GB/T6569 | ≥300 | >250 | >250 | ≥300 | >250 |

| Hardness | HV5 | ASTM C 1327 | >1600 | >1100 | >1100 | >1600 | >1100 |

| Fracture thoughness | MPa*m1/2 | ASTM C1 421 | 4 | 4 | 4 | - | - |

| Young’s modulus | Gpa | EN_ 15042-1 | 370 | - | 330 | 370 | 330 |

| Coefficient of linear expansion | *10-6/ºC | GB/T7320-2U08 | - | - | - | - | - |

| T1 | 200°C | - | - | - | - | 6.2-6.8 | 6.2-6.8 |

| T2 | 500ºC | - | - | - | - | 7-7.4 | 7-7.4 |

| T3 | 800ºC | - | 8.3 | 8.1 | 8.1 | 7.7-8 | 7.7-8 |

| Thermal conductivity | W/m-K @25ºC | ASTM7461 | 30 | 24 | 24 | ≥27 | ≥20 |

| Volume resistivity | Ω.cm | ASTM D257 | ≥1014 | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Specific heat | J/g.K | ASTM1461 | 1.1 | 0.8 | 0.8 | 0.8-0.9 | 0.8-0.9 |

| Dielectric strength | KV/mm | ASTM D749 | ≥20 | ≥15 | ≥15 | ≥20 | ≥15 |

Above parameter values apply to standard specimens only and would change according to different shape, size and manufacturing process of products. Other materials can be provided upon request.